Position

PTC works with GILL Sensors & Controls to supply a wide range of non-contact position sensors for linear, angular and rotary position measurement. Gill position sensors are true non-contact devices with a constant air gap between the sensor and the moving target. This ensures that no mechanical wear is experienced through use, providing excellent long-term reliability especially in dusty and dirty environments.

1. Blade25

- Movement Type: Linear & Angular

- V Supply: +4.8V to +32V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

2. Blade60

The Blade60 is a solid-state inductive position sensor with a configurable 60mm measurement zone, capable of monitoring linear and shallow-arc movement.

- Measurement Zone: 60mm

- Movement Type: Linear & Shallow Arc

- V Supply: +4.8V to +30V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

Video: How The Blade60 Position Sensor Works

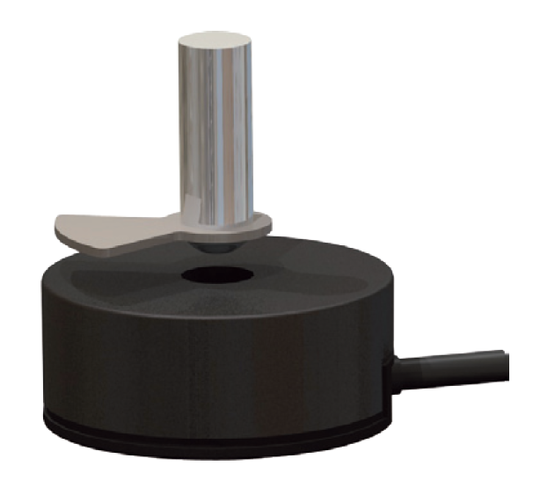

3. Blade360

The Blade360 is a non-contact inductive rotary position sensor with fully configurable 0-360° measurement range. Fully sealed, submersible and suitable for extreme environments.

- Measurement Range: 360°

- Movement Type: Rotary

- V Supply: +4.8V to +32V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

Video: How The Blade360 Position Sensor Works

4. Dual Cavity

The Dual Cavity is a non-contact displacement transducer capable of monitoring linear and angular movement, with the range determined by the shape of the target ‘activator’

- Movement Type: Linear & Angular

- Measurement Range: Determined by activator shape

- V Supply: +6V to +30V

- Output: 0-4.2V

- Sealing: IP67

Video: How Dual Cavity Position Sensor Works

Position

PTC works with GILL Sensors & Controls to supply a wide range of non-contact position sensors for linear, angular and rotary position measurement. Gill position sensors are true non-contact devices with a constant air gap between the sensor and the moving target. This ensures that no mechanical wear is experienced through use, providing excellent long-term reliability especially in dusty and dirty environments.

1. Blade25

- Movement Type: Linear & Angular

- V Supply: +4.8V to +32V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

2. Blade60

The Blade60 is a solid-state inductive position sensor with a configurable 60mm measurement zone, capable of monitoring linear and shallow-arc movement.

- Measurement Zone: 60mm

- Movement Type: Linear & Shallow Arc

- V Supply: +4.8V to +30V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

Video: How The Blade60 Position Sensor Works

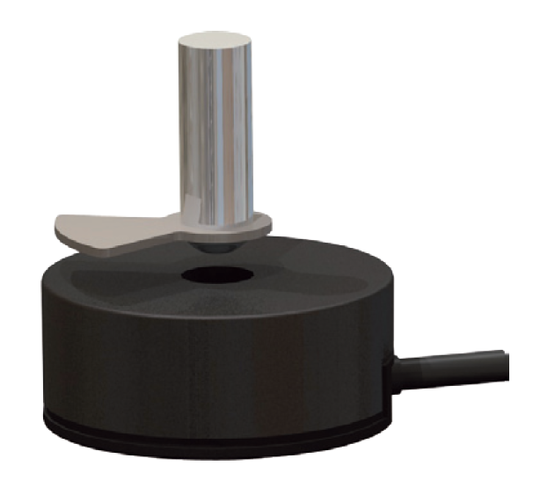

3. Blade360

The Blade360 is a non-contact inductive rotary position sensor with fully configurable 0-360° measurement range. Fully sealed, submersible and suitable for extreme environments.

- Measurement Range: 360°

- Movement Type: Rotary

- V Supply: +4.8V to +32V

- Outputs: Analogue, PWM, Serial, Switch

- Sealing: IP67

Video: How The Blade360 Position Sensor Works

4. Dual Cavity

The Dual Cavity is a non-contact displacement transducer capable of monitoring linear and angular movement, with the range determined by the shape of the target ‘activator’

- Movement Type: Linear & Angular

- Measurement Range: Determined by activator shape

- V Supply: +6V to +30V

- Output: 0-4.2V

- Sealing: IP67

Video: How Dual Cavity Position Sensor Works

Would like to obtain more info and learn more of its applications?